I. Pourquoi la fuite de HCl est-elle toujours « indétectable » ?

Dans l'atelier d'électrolyse d'une usine de chlore-soude, les opérateurs ont senti une odeur irritante, mais le détecteur portatif indiquait « 0 ppm ». Lorsqu'une sonde à longue perche a été insérée dans les interstices des brides de canalisation, la mesure est passée à 20 ppm. La raison en est que le gaz HCl s'accumule dans les espaces étroits, difficiles d'accès pour les positions de détection conventionnelles.

II. Précautions pour la détection du HCl

1. Seuils de danger du HCl

Seuil olfactif : 0,5 ppm ; des concentrations > 5 ppm provoquent immédiatement de la toux et une oppression thoracique

Concentrations > 50 ppm : peuvent entraîner un spasme du larynx, un œdème pulmonaire, voire la mort

2. Difficultés de détection

1.Le HCl est très soluble dans l'eau. Lorsque l'humidité dépasse 85 %, il forme un brouillard acide qui adhère à la surface de la sonde et empêche la détection

2.Les points de fuite se situent principalement dans des zones étroites telles que les garnitures de vannes et les joints de brides, difficiles d'accès avec les méthodes d'échantillonnage conventionnelles

3. Points clés opérationnels

1.Équipez-vous d'une longue tige d'échantillonnage (longueur ≥ 1,5 mètre) pendant la détection afin d'atteindre les interstices pour les tests

2.Nettoyez la sonde avec de l'eau déionisée chaque semaine pour éliminer les résidus de brouillard acide

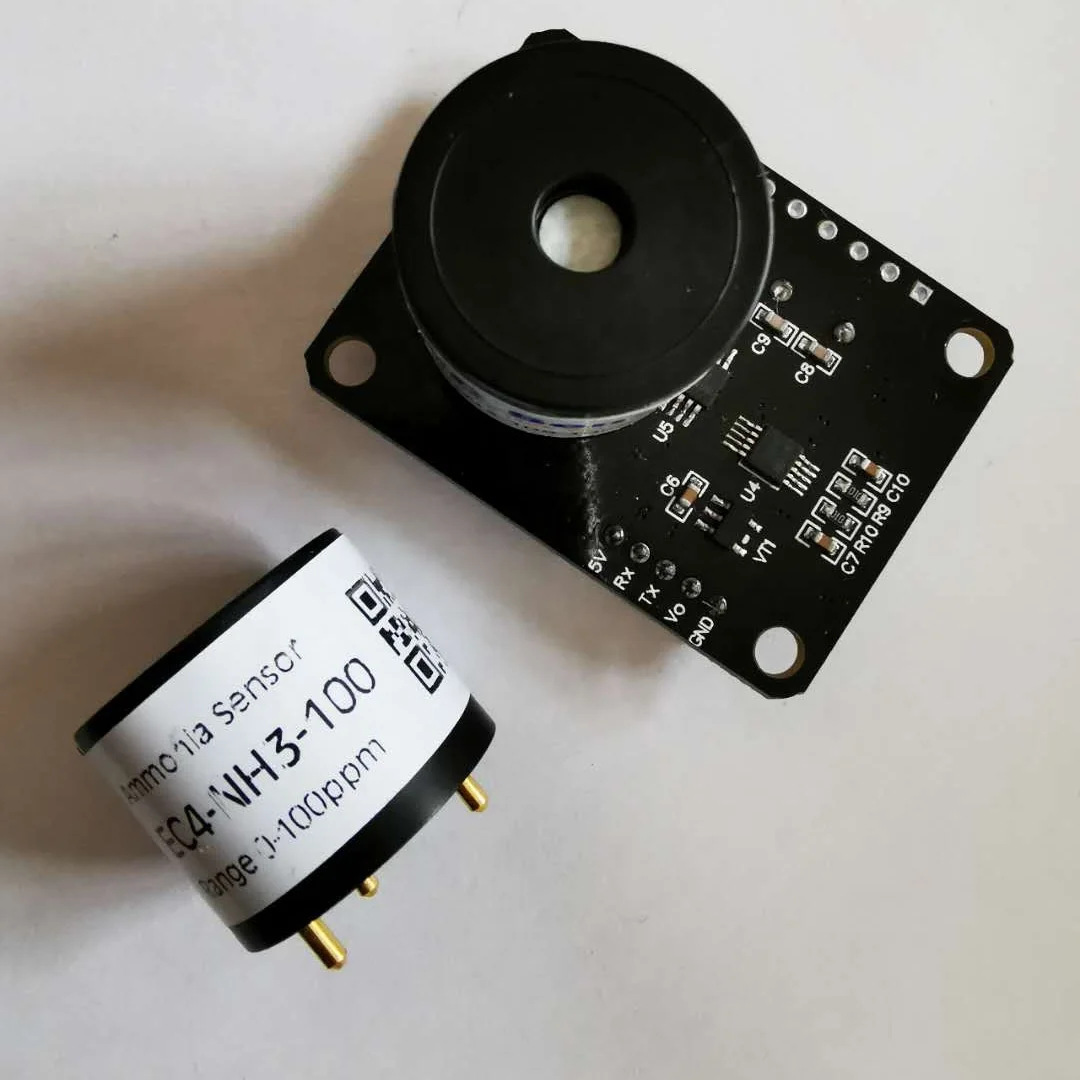

III. Solution : MST 101Portable HCL Détecteur de gaz + pompe d'échantillonnage de gaz + tube d'échantillonnage prolongé

Caractéristiques principales :

-

✔ Conception résistante à l'humidité : La sonde est équipée d'une membrane filtrante en PTFE (polytétrafluoroéthylène) pour éviter le blocage par le brouillard acide

-

✔ Plage de détection : 0-500 ppm ; résolution : 0,1 ppm, capable de détecter des fuites infinitésimales

-

✔ Tige d'échantillonnage + tuyau d'extension de 3 mètres, adapté pour la détection dans des espaces restreints

-

✔ Un détecteur portable de gaz unique combiné à une pompe manuelle peut être transformé en détecteur à aspiration par pompe

Retour d'expérience utilisateur :

Après avoir utilisé cette solution, une usine de chlore-soude a augmenté son taux de détection des fuites de HCl à 100 %.

Avez-vous rencontré le problème de « fuite par omission de joint » lors de la détection de HCl ? Envoyez un message privé avec « Vérification des angles morts » pour obtenir une feuille de route de détection personnalisée !

Actualités à la Une

Actualités à la Une